reduced circuit board manufacturing costs.

Our extensive testing results in the following benefits:

Our testing equipment has been carefully chosen to impose the most comprehensive, demanding and reliable burn-in and temperature cycling processes among our competitors. Given WORLD’s extensive experience with these processes, we have refined our manufacturing process such that they now result in the failure of only a small number of assembled products, making manufacture quicker and more reliable. This form of the environmental stress test is designed to replicate real-world conditions, where the products of our clients will be used at both high and low temperatures and will experience failures like power surges.Īfter burn-in testing, we can better understand the load capacity of any given component, and say with certainty that the product meets our clients’ specifications. Temperature cycling is a similar process, whereby the components are tested first at a low temperature, and then at a high temperature. This leaves behind only those components that WORLD can be sure will only fail after extensive, hard-wearing use, a significant benefit for all our clients.īurn-in testing is conducted at an elevated temperature, and in certain cases, at an elevated voltage. Any components that fail during the initial phase of the so-called bathtub curve are removed and replaced. WORLD is capable of testing throughout the manufacturing process, or simply at its conclusion.ĭuring the burn-in process, it becomes possible to detect any components that will fail not because of a specific physical defect, but because of a more general failure of quality control during assembly. The goal of this process is first to ensure that the components generally meet the specification for our clients’ various goals, and second to weed out any accidents of the manufacturing process which affected specific, individual components.

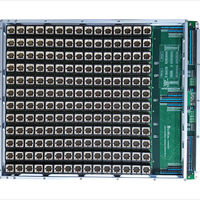

#Burnin board trial

The burn-in is a common testing process whereby the components of a given system are put through a trial run prior to their release for sale, and occasionally prior to assembly. We also put every circuit board through temperature cycling so that our clients can rest assured of the quality of their finished product.

As such WORLD complete an exhaustive and thorough burn-in testing process. It is critical for our customers to locate product flaws before their circuit boards reach the market. Supply chain management has crossed over from being a narrow management function to being a key operational function. Our engineers can develop a set of tests that ensure reliability and high performance in all products. This quality is what underpins our commitment to thorough testing. WORLD electronics is dedicated to quality. This combination grants our customers the benefit of turning new designs quickly and accurately. Our flexible manufacturing floor layout and highly trained staff allow for Quick Set-up and Tear Down of small volume prototype runs. Our team of engineers assists you in the development of new designs to optimize quality manufacturability (DFM) and testability, resulting in cost minimization and reduced product development time. Our commitment to quality and service is second to no supplier. WORLD electronics offers a complete line of electronic circuit board manufacturing and assembly services, as well as advanced manufacturing services.

0 kommentar(er)

0 kommentar(er)